Gambro was founded in Sweden in 1964 and has production facilities in nine countries with sales in more than 100 countries. Today, the company employees 8,000 people around the globe. For decades, Gambro has been first to the market with many groundbreaking innovations. By designing and delivering solutions to dialysis clinics and intensive care units, Gambro offers not just improved treatment quality, but also improved efficiency.

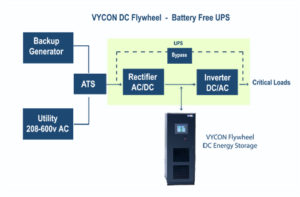

Gambro is one of three companies in the world that meets the demand of the dialyzer, also known as an artificial kidney. Any disruption in the sophisticated and automated manufacturing process can result in an eight to 10-hour clean-up and restart process – not acceptable when patients need this life saving device. When the manufacturing process goes down, it’s usually due to a power problem from the local utility. David Ganus, Facilities Engineer for Gambro Renal Products, needed to have a power system in place that could mitigate the frequent power disturbances from the local utility provider that frequently switches from one grid to another. To assure processes continue to run smoothly, Gambro depends on efficient uninterruptible power systems (UPSs) as well as the clean energy storage solution of the VYCON Direct Connect (VDC) flywheel. Due to the flywheels very quick response time to power anomalies and the fact that 99 percent of the power disturbances Gambro experiences only last seconds, a UPS with flywheel backup was the perfect solution. The VDC-XE units work seamlessly with energy-efficient three-phase UPS units, but take up a third of the room of comparably-sized batteries. “Since we’ve had the UPS and flywheels in place, we’ve experienced several voltage sags from the utility. The UPS and flywheels have performed exactly how they’re supposed to,” said Ganus.

Gambro is one of three companies in the world that meets the demand of the dialyzer, also known as an artificial kidney. Any disruption in the sophisticated and automated manufacturing process can result in an eight to 10-hour clean-up and restart process – not acceptable when patients need this life saving device. When the manufacturing process goes down, it’s usually due to a power problem from the local utility. David Ganus, Facilities Engineer for Gambro Renal Products, needed to have a power system in place that could mitigate the frequent power disturbances from the local utility provider that frequently switches from one grid to another. To assure processes continue to run smoothly, Gambro depends on efficient uninterruptible power systems (UPSs) as well as the clean energy storage solution of the VYCON Direct Connect (VDC) flywheel. Due to the flywheels very quick response time to power anomalies and the fact that 99 percent of the power disturbances Gambro experiences only last seconds, a UPS with flywheel backup was the perfect solution. The VDC-XE units work seamlessly with energy-efficient three-phase UPS units, but take up a third of the room of comparably-sized batteries. “Since we’ve had the UPS and flywheels in place, we’ve experienced several voltage sags from the utility. The UPS and flywheels have performed exactly how they’re supposed to,” said Ganus.