Texas Scottish Rite Hospital for Children is a world leader in the treatment of pediatric orthopedic conditions. The hospital and its staff strive to improve the care of children worldwide through innovative research and teaching programs, training physicians from around the world. As a leading pediatric orthopedic center, the hospital has treated more than 210,000 children since its inception, with more than 40,000 clinic visits each year. Selected as one of the Best Children’s Hospitals by U.S. News and World Reports, the hospital takes a multidisciplinary approach to care, tailoring treatment to the individual needs of each child and family.

Texas Scottish Rite Hospital for Children is a world leader in the treatment of pediatric orthopedic conditions. The hospital and its staff strive to improve the care of children worldwide through innovative research and teaching programs, training physicians from around the world. As a leading pediatric orthopedic center, the hospital has treated more than 210,000 children since its inception, with more than 40,000 clinic visits each year. Selected as one of the Best Children’s Hospitals by U.S. News and World Reports, the hospital takes a multidisciplinary approach to care, tailoring treatment to the individual needs of each child and family.

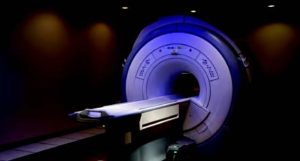

Helped by supporters throughout the country, Texas Scottish Rite Hospital for Children (TSRHC) has emerged as one of the nation’s leading medical centers for the treatment of pediatric orthopedic conditions, as well as certain related neurological disorders and learning disorders, such as dyslexia. With its specialty of orthopedics, great care and attention is paid to the hospital’s Imaging Suite, ensuring that the Magnetic Resonance Imager (MRI) and Computerized Tomography (CT) scanning systems are fully operational

24×7. The hospital’s imaging equipment includes a state-of-the-art CT scanner and a MRI scanner housed in the hospital’s Seay/Pickens MRI Center. A main objective for Engineering Department Director John Coté is to make sure the imaging equipment, 64-slice Philips Brilliance CT and Signa HDxt 1.5T MRI, operates at peak performance levels around the clock.

Imaging Systems Require Clean, Pure Electrical Power

Power brownouts, surges and outages can have devastating effects on MRI equipment – especially to its refrigeration system. Without clean electrical power supplied to the MRI vacuum pump/cold head to keep the cryogen liquefied, the cryogen will begin to boil off. Depending on the design of the cryogen vent and the rate the cryogen is boiling off, the cryogenic gas discharge may freeze any accumulated water in the cryogen vent, blocking the pipe and increasing the odds for a cryogen vent breach in the event of a quench. Quenching refers to the events that occur when the liquid cryogens that cool the magnet coils boil off rapidly, which results in helium escaping very rapidly from the cryogen bath. Because a quench results in rapid loss of cryogens from the magnet, recommissioning the magnet is expensive and time consuming. If power is not restored to the vacuum pump, at some point the magnet will quench, discharging most of its remaining cryogenic gases.

At times, the electricity from the power substation to the hospital is not consistent for MRI and CT operations. “While we don’t often experience power blackouts, small voltage drops or surges in power can damage the unit’s refrigeration systems as well as prompt a hard shutdown of the MRI equipment,” said Coté.

Flywheels Spin Up Power Quality

To mitigate unstable power, Coté and his team depend on a three-phase uninterruptible power supply (UPS) and two of VYCON’s 300kW VDC-XE flywheel systems to deliver clean, reliable power to the imaging suite. If there is a power outage or if the power coming in from the utility is “dirty,” the UPS will generate smooth high-quality power from the flywheels. Many UPSs depend on valve-regulated lead-acid (VRLA) batteries as their energy storage solution. Unfortunately, lead-acid batteries degrade every time they are cycled (used), and one bad cell in the battery bank can take out the others, rendering the battery bank useless. Moreover, batteries take up a lot of space, require expensive cooling and contain hazardous chemicals, making disposal an issue.

Every time a battery is used, it becomes less responsive to the next event. Batteries generate heat, and heat reduces battery life. Batteries can also release explosive gases that must be ventilated away. Hazmat permitting, acid leak containment, floor-loading issues, slow recharge times, lead disposal compliance and transporting are important issues that have to be dealt with.

These issues led Coté to implement flywheels over batteries. “Power reliability for our imaging suite is paramount. We were also severely constrained by available real estate for our power equipment. Due to the flywheels’ small footprint and no requirement for dedicated cooling, we were able to locate the UPS and two flywheels in the radiology suite. We couldn’t have done this using batteries,” said Coté.

Flywheel Basics

VYCON’s VDC-XE flywheel system replaces lead-acid batteries used with UPSs and works like a dynamic mechanical battery that stores energy kinetically by spinning a mass around an axis. Electrical input spins the flywheel rotor up to speed, and a standby charge keeps it spinning 24×7 until called upon to release the stored energy. The amount of energy available and its duration is proportional to its mass and the square of its revolution speed. For flywheels, doubling mass doubles energy capacity, but doubling rotational speed quadruples energy capacity:

E = kMω2

k – Depends on the shape of the rotating mass

M – Mass of the flywheel

ω – Angular velocity

Benefits of VYCON’s Clean Energy Storage Solution:

- 20x reliability vs. VRLA batteries

- High-power density, small footprint

- Parallel capability that allows for future expansion • Fast recharge

- Full monitoring for predictive performance • No hazmat Requirements

- Low maintenance

- 20-year useful life

- Simple installation

- N+1 redundancy Options

- Quiet operation

- Wide temperature Tolerance

- High efficiency

During a power event, the flywheel will supply backup power seamlessly and instantaneously, providing instant power to the connected load exactly as it would do with a battery string. It’s important to know that according to the Electric Power Research Institute (EPRI), 80 percent of all utility power anomalies/ disturbances last less than two seconds, and 98 percent last less than 10 seconds.

Return on Investment

The latest flywheel designs sold by world leaders in threephase UPS systems take advantage of higher speeds and full magnetic levitation packing more green energy storage into a much smaller footprint. Thanks to VYCON’s patented flywheel technology, VYCON’s flywheels do not require any kind of bearing maintenance requirements. This is important, as some flywheels on the market today require bearing maintenance and replacement to the tune of nearly $10,000 for each flywheel every few years. In addition, bearing maintenance requires the system to be shut down for six to eight hours – not realistic in hospital environments. The overall cost-benefit ratio of VYCON’s systems is very attractive. Over a 20-year design lifespan, cost savings from a hazmat-free flywheel versus a 5-minute valve regulated lead-acid (VRLA) battery bank are in the range of $100,000 to $200,000 per flywheel deployed.

The latest flywheel designs sold by world leaders in threephase UPS systems take advantage of higher speeds and full magnetic levitation packing more green energy storage into a much smaller footprint. Thanks to VYCON’s patented flywheel technology, VYCON’s flywheels do not require any kind of bearing maintenance requirements. This is important, as some flywheels on the market today require bearing maintenance and replacement to the tune of nearly $10,000 for each flywheel every few years. In addition, bearing maintenance requires the system to be shut down for six to eight hours – not realistic in hospital environments. The overall cost-benefit ratio of VYCON’s systems is very attractive. Over a 20-year design lifespan, cost savings from a hazmat-free flywheel versus a 5-minute valve regulated lead-acid (VRLA) battery bank are in the range of $100,000 to $200,000 per flywheel deployed.

Advanced Technology for an Advanced Hospital

Prior to incorporating the flywheels, the hospital’s MRI suite experienced power problems causing the MRI system to completely shut down. “This can be especially problematic for patients when under anesthesia, as the child has to be awakened and the imaging rescheduled. This has happened at least twice before we installed the flywheel systems,” said Tina Reese, Director of Radiology for TSRHC.

“We are pleased with the flywheel’s performance. The green aspects of the flywheels were also of interest to us. Not having to deal with batteries was a plus. By incorporating flywheels as the energy storage part of the UPS, the hospital has saved time and money, but more importantly, is delivering predictable operation of our imaging suite for our special little patients,” said Coté.