Located outside of Kansas City, Cavern Technologies’ data center is located 125-feet deep underground in a 3-million-square-foot facility. Fortified by a natural limestone bunker that is three times stronger than concrete, the data center is protected from natural and deliberate disasters, has a consistent 68° ambient temperature and is further fortified by best-in-class biometric and facial recognition security systems.

As a top provider in the development, leasing, and operation of build-to-suit wholesale data centers, Cavern’s environmentally regulated, secure infrastructure is SSAE 16 SOC 1 Type II and SOC 2 Type II certified which helps to streamline the process for enterprise customers to comply with industry regulations, such as HIPPA and PCI DDS. Cavern’s fully redundant infrastructure is designed to meet the specialized power, cooling and security requirements its customers require to house IT systems that support their mission-critical business processes.

“Cavern’s electrical equipment must be of the highest reliability in order to have a low corrective maintenance facility,” said Mike McDaniel, vice president of facility engineering for Cavern Technologies. “Of course, uptime is job one for us. Our clients come to us for the highest level of uptime, so maintaining full redundancy of our infrastructure equipment is a requirement for our business.”

For electrical power, Cavern partners with Kansas City Power and Light Company (KCP&L) to provide robust power. Cavern has N+1 redundancy on its generators and 2N redundancy on its dual-conversion UPSs, PDUs, and RPPs. During a recent expansion, McDaniel wanted to find a more reliable and less maintenance solution to lead-acid batteries being used with their UPS systems. Through research and working with local IT infrastructure experts at ITS Solutions, McDaniel was convinced that highly reliable flywheel energy storage systems were the way to go.

“All of our critical loads are now protected by four 2N-designed 300kVA dual-conversion UPSs paired with four of VYCON’s 300kW VDC flywheels,” said McDaniel. “We still have legacy UPSs that carry many of our customer’s loads, so this is only for customers online within the last two years. Going forward, all new customer loads will be on the flywheel design.

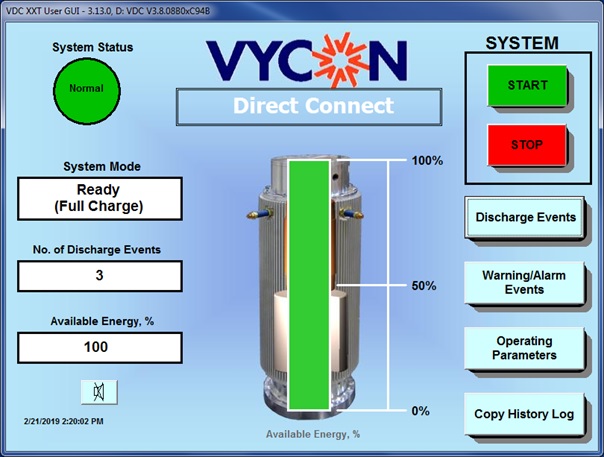

The unique design of the VYCON VDC flywheel enables it to hold kinetic energy in the form of a rotating mass, and then convert this energy to electric power through patented technology within the flywheel system. A high-speed motor generator, active magnetic bearings that levitate and sustain the rotor during operation, and a control system that provides vital information on system performance.

These innovative technologies enable the VYCON flywheel to charge and discharge at high rates for countless cycles making conventional technologies like batteries obsolete.

As a battery-free solution, flywheel energy storage is ideal for a variety of applications including data centers, healthcare facilities, broadcast stations, and other mission-critical operations that require up to 20 to 40 seconds of backup power. Additional benefits include a 20-year life, small footprint, very little maintenance and no need to be installed in an environmentally controlled (air-conditioned) location.

For McDaniel, selecting a new energy storage solution was predicated on reliability and durability. “Knowing the available energy level at any point in time is a key differentiator for flywheels versus batteries. Given the ability of our generator plant to be online in under 10 seconds, the VYCON flywheels were a perfect fit for our design.”

Using a flywheel versus a five-minute valve-regulated-lead-acid (VRLA) battery bank can offer $100,000 to $200,000 in cost savings per flywheel deployed. And, with VYCON’s contact-free magnetic levitation system, there are no bearings to replace – saving customers tens of thousands of dollars in bearing replacements needed with other flywheel-based systems.

“Since the flywheels have been installed, we have performed in house testing as well as have experienced a few weather and utility power issues. In each occurrence, the flywheels have performed flawlessly,” noted McDaniel.